Conveyor chains benefit food, pharmaceutical production

ZMC CHAINS BMG's range of ZMC conveyor chains can be used for bakery proofers, which are an integral part of the industrial process to produce numerous bakery products

A CHAIN MEDLEY The range of ZMC chains for special applications is manufactured with the appropriate combination of materials, heat treatments, surface coatings, geometry and precise dimensions to cope efficiently with complex challenges

Industrial solutions provider BMG has a comprehensive range of power transmission components, including Italian-manufactured ZMC industrial conveyor chains, that offer dependable service in diverse applications, particularly in food and pharmaceutical production and packaging.

“BMG’s ZMC solutions for the food and beverage sector extend from the processing of raw ingredients, to baking, bottle washing, packaging and safe distribution,” says BMG power transmission division business unit manager Carlo Beukes.

“Our team of specialists advises customers at food and beverage plants to only invest in quality branded conveyor components that are manufactured in food-compliant materials – [such as] stainless steel – for highly-specialised and safety-critical applications in food manufacturing and preparation,” he adds.

Beukes also says that problems associated with corrosion, thermal shock resistance, durability and resistance to powerful cleaning detergents can also be reduced by using stainless-steel components, which is highly advantageous for operational processes.

“Stainless-steel chains are also recommended because this material has low magnetic permeability and is highly resistant to both alkali and acidic environments,” he says.

The ZMC portfolio, which is manufactured to stringent international quality specifications, comprises standard and special application chains and is available from BMG in a range of dimensions, mechanical characteristics and geometries.

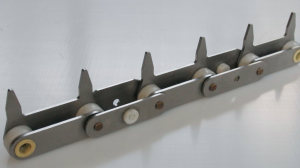

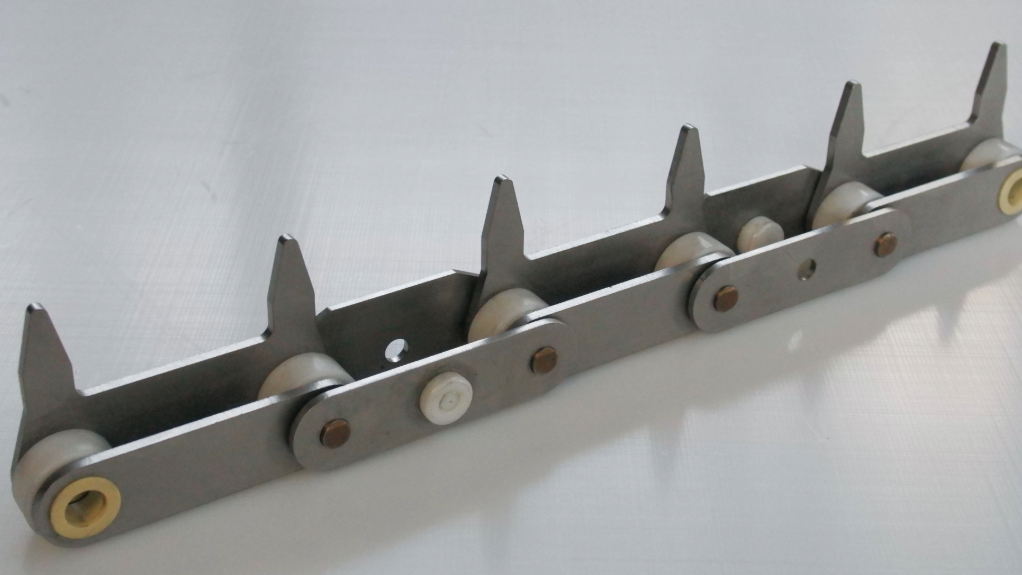

Additionally, BMG’s ZMC metric and imperial chains are available with solid, hollow or extended pins, with bushings, rollers or bearings mounted at the centre of the links. Chains are also offered with holes in the links, designed especially for the subsequent assembly of the necessary components. BMG also supplies sprockets, with or without a hub, suitable for each type of chain.

The range of ZMC chains for special applications is manufactured with the appropriate combination of materials, heat treatments, surface coatings, geometry and precise dimensions to cope with complex challenges.

BMG specialists advise on materials and coatings based on factors such as load, speed, temperature, humidity and contact with process fluids or steam.

The company also offers a measuring service, which makes it possible to assemble the chains on the system by “perfectly matching them”, to ensure maximum precision and uniformity of length. This prevents product waste by perfectly aligning dual strand conveying systems, says Beukes.

The main applications for ZMC stainless-steel conveyor chains in the agri-food industry are in machines used to select fruit and vegetables according to size and weight, and for processing and packaging products.

They can also be used for bakery proofers, which are an integral part of the industrial process to produce numerous bakery products, including bread, crackers, breadsticks, rusks, pizza, biscuits and sweets.

Depending on the size and characteristics of the product and specific performance requirements, the proofer can be modified or constructed in multiple states, using vertical and horizontal stainless-steel conveyors to carry the trays, baking tins or slats, on which the products to be leavened are deposited.

Fundamental parameters for the design of the system include speed, transported load, temperature and other environmental conditions, as well as scheduled maintenance. With the choice of various materials, it is possible to produce chains capable of working at temperatures of up to 500 °C.

The main configurations for food baking ovens with conveyor chains are horizontal wire net or slats. In wire net ovens, the chains are generally produced with hollow pins, while for the slats, numerous chain and attachments has been developed – some of which have protruding pins and outboard rollers. In this sector, ZMC’s self-lubricating Mecasec technology can be used in temperatures of up to 250 °C.

Bottle washer chains require high strength and long wear life without lubrication. For part of the bottle washing process the chain must work while immersed in water and diluted detergent and is often polluted by abrasive elements from the glass bottles, such as dust and paper residues.

For high efficiency in bottle washing systems, BMG specialists recommend the use of high-performance, stainless-steel ZMC bottle washer chains, which are available with attachments that have welded internal screws for securely fixing the crossbars on which bottles are transported.

Other applications for ZMC chain are for conveyors in complex assembly lines in automotive manufacturing plants, cement production and in timber and sugar mills.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation